This comprehensive guide provides a step-by-step approach to mastering the 10-speed transmission in a tractor-trailer, covering basic techniques, advanced strategies, and troubleshooting common issues. Whether you're a new driver or looking to refine your skills, this guide will equip you with the knowledge and confidence to shift smoothly and efficiently. Mastering the 10-speed is crucial for fuel efficiency, vehicle longevity, and, most importantly, safe operation. For more detailed information, check out this helpful resource.

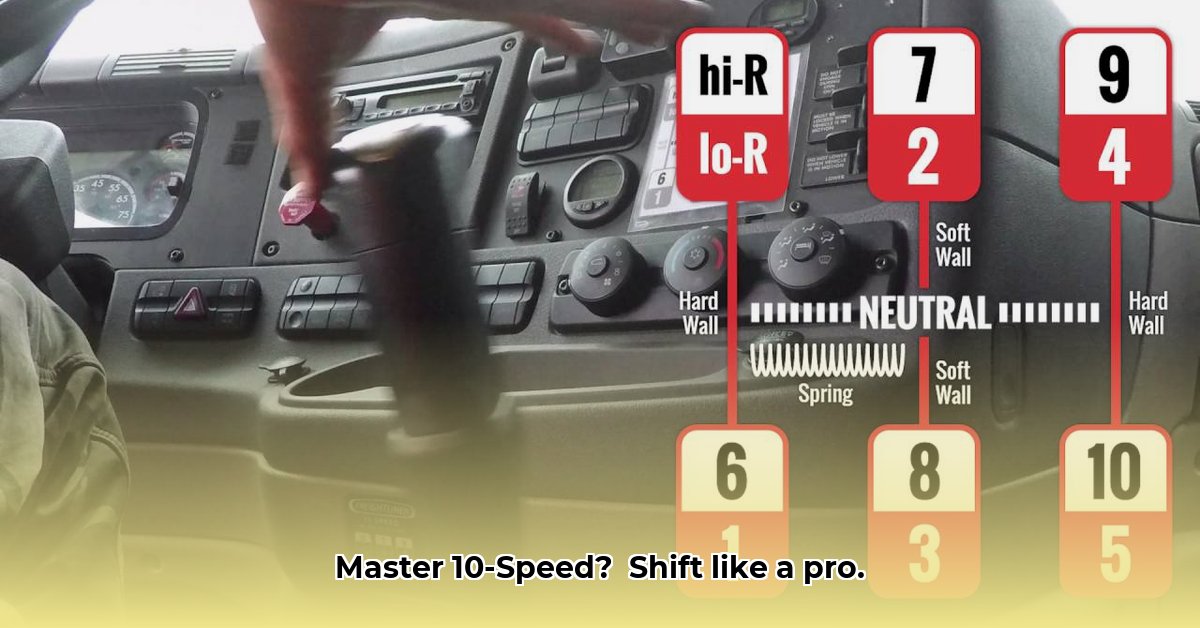

10-Speed Tractor Trailer Shift Pattern: Fundamentals

Smooth shifting is key to efficient and safe operation of a 10-speed transmission. It's a coordinated effort between your feet and hands, requiring practice to develop the correct feel. Improving your shifting technique will lead to smoother driving, better fuel economy, and reduced wear on the truck and transmission. Don’t be discouraged by the initial learning curve; with time and practice, you will become proficient.

Basic 10-Speed Shifting: Getting Started

Mastering basic shifting is the foundation for all advanced techniques. The process involves three key steps: clutch engagement, gear selection, and clutch disengagement combined with throttle control.

Clutch Engagement: Fully depress the clutch pedal before shifting. This disconnects the engine from the transmission.

Gear Selection: Carefully move the gear lever to the next gear in the 10-speed pattern. Take your time and ensure the lever is firmly engaged.

Clutch Release and Throttle Control: Gradually release the clutch pedal while simultaneously adjusting the accelerator to maintain a proper engine speed (RPM). This coordination is vital. Too fast a release or a mismatched RPM leads to grinding. Listen to your engine and feel the truck— it’s essential to find the "sweet spot."

Is proper RPM crucial for smooth shifting? Absolutely! Matching engine speed to the selected gear minimizes strain on the transmission and enhances shifting smoothness. Finding the correct RPM through practice and feel is essential.

Advanced Techniques and Troubleshooting: Refining Your Skills

Once you’ve mastered the basics, focus on advanced shifting techniques and troubleshooting. Smooth shifts are essential for efficient operation and longer equipment life. Proper maintenance is crucial to avoiding mechanical problems and ensuring longevity.

- Double Clutching: Double-clutching (momentarily engaging neutral before downshifting) synchronizes engine and transmission speeds, leading to smoother downshifts, especially while hauling heavy loads or descending hills.

- Missed Shifts: If you miss a gear, gently depress the clutch, select the correct gear, and try again. Missed shifts usually stem from poor clutch control or improper RPM matching.

- Gear Grinding: Grinding noises indicate a mismatch between engine speed and gear selection. Ensure the clutch is fully depressed and check engine RPM. Persistent grinding suggest a potential mechanical issue—consult a mechanic.

What is the impact of improper gear selection on fuel efficiency? Improper shifting significantly impacts fuel economy. Smooth, efficient shifting conserves fuel—a considerable cost factor in long-haul trucking.

Safety and Efficiency on the Road: Best Practices

Safe operation of a heavy vehicle requires planning and attention to detail. Gear selection is critical on hills to prevent rollbacks. Mastering engine braking techniques, a key component of safe downhill driving, is essential for safe operation.

Here are some key safety considerations:

Proper shifting and attention to road conditions reduce the risk of accidents. Safe driving is a combination of technique and vigilance.

| Potential Hazard | Prevention Strategy | Mitigation Technique |

|---|---|---|

| Runaway truck on hills | Pre-plan gear selections, utilize engine braking | Select lower gears for increased engine braking; control speed carefully. |

| Missed shifts | Master clutch operation, precise RPM matching | Correct gear selection; try again slowly. |

| Gear Grinding | Regular maintenance, including fluid checks | Use controlled movements when shifting; seek mechanical inspection if needed. |

How does regular maintenance contribute to safe and efficient operation? Regular maintenance, including transmission fluid checks, prevents mechanical issues and ensures smooth, reliable operation.

This guide provides a solid foundation for mastering 10-speed shifting. Remember, consistent practice, attention to detail, and a commitment to safe driving habits are paramount. Through continuous practice, you’ll develop confidence and precision in every shift, making your driving more efficient and a safer experience for both yourself and others on the road.